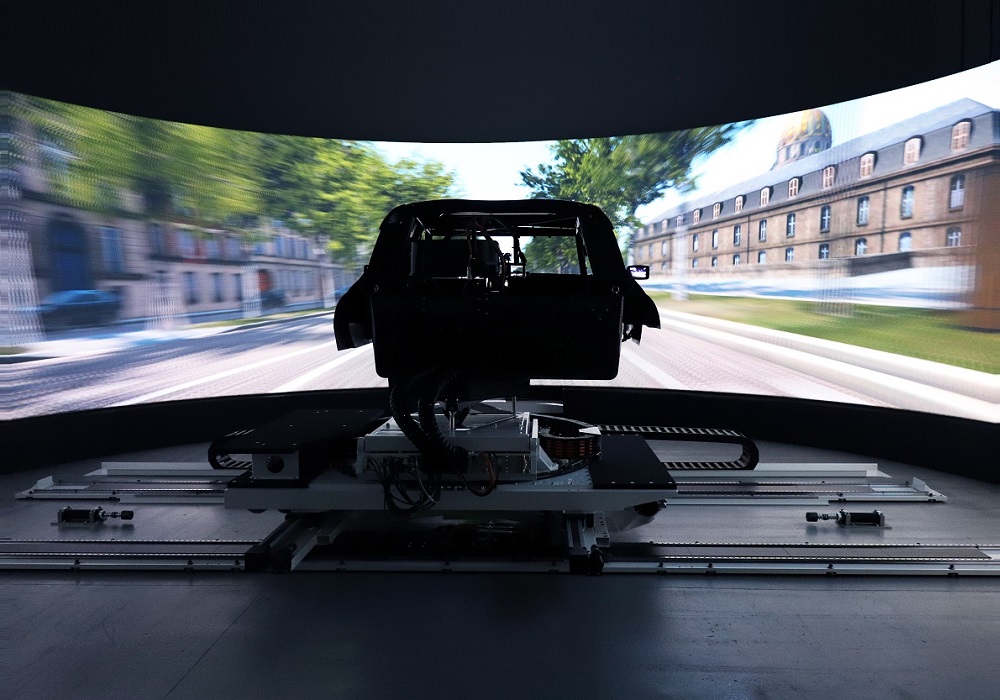

This is a video overview of the Stratiform 3 (S3) motion system, our latest 6-DOF primary motion system, as used in our Delta series dynamic DIL simulators. With the S3 we have built upon our original stratiform motion system designs and extended it to provide high fidelity, longer duration motions, keeping our trademark high-dynamic capability.

The results are high accelerations, high velocities, long displacements with high bandwidth and precise motion at lower velocities for smooth reproduction of subtle vehicle attributes. Many key driving manoeuvres can be conducted 1:1 with the real world, for unparalleled realism.

2009: Stratiform Motion System

We asked ourselves this question: What might an automotive driving simulator look like if we began with a clean sheet of paper? The AML SMS1TM (Stratiform Motion System 1) was the result.

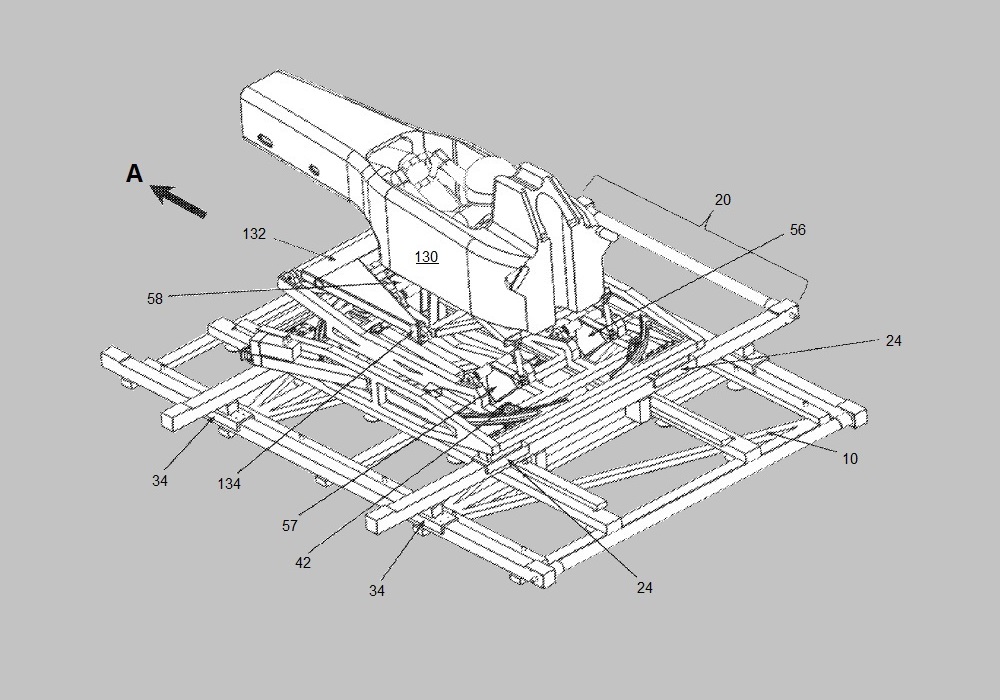

We departed from the popular but limited hexapod, and invented a 6-DOF motion system built in logical layers corresponding to primary vehicle axes. It would be linear, agile and highly dynamic. Ansible Motion was born.

2009-2011: Ansible Motion takes flight

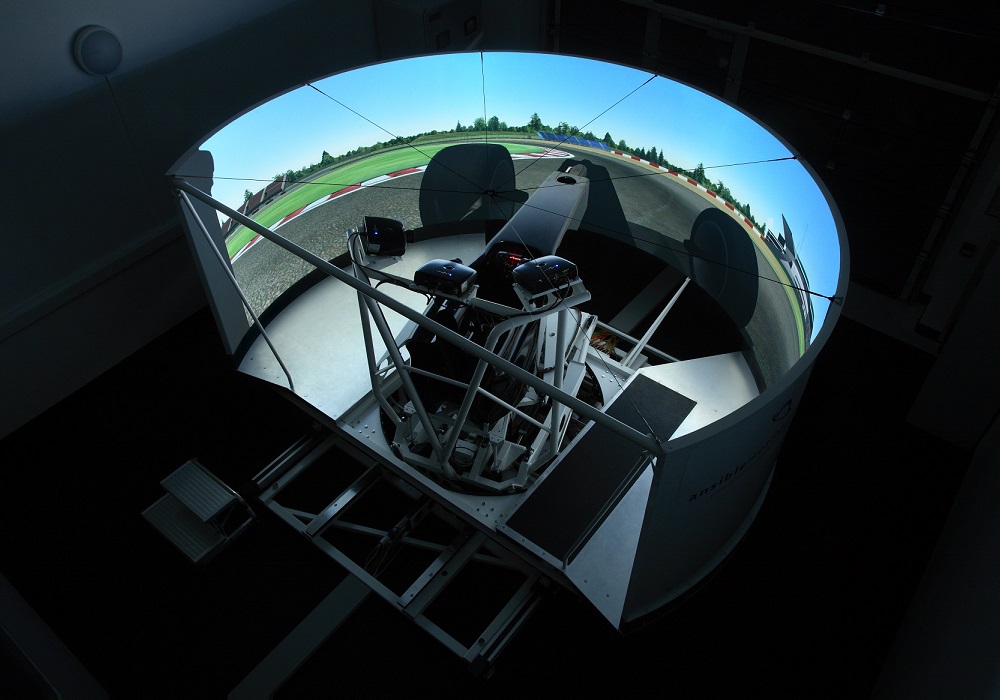

Our earliest S1 (Stratiform 1) simulators had a patented dynamic vision system with an extremely small footprint. Some of our customers began inquiring about larger simulators with more motion space and heavier payloads, so we began work on a new, stationary vision system solution.

2011-2013: Stratiform evolution

While our new stationary vision system was taking form, it was time for our Stratiform Motion System to make its first evolutionary jump. We began work on what would become the S2 (Stratiform 2). Improved construction; larger payload capacity (350 kg); larger vision systems (6-9m diameter).

2013-2019: Driver-in-Loop comes of age

The S2’s flexibility and scalability were keys to success for our Delta series in a customer space that was rapidly mainstreaming Driver-in-the-Loop simulation. Case in point: the S2 organically gave rise to our QCS® Quick-change Cabin System.

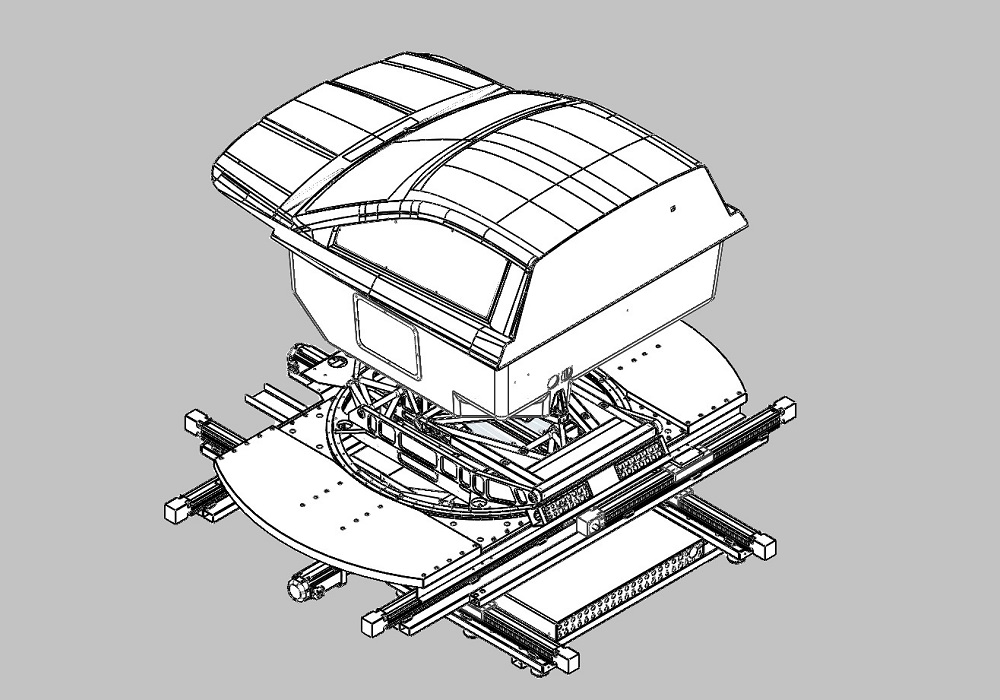

2019: Stratiform stretches its legs

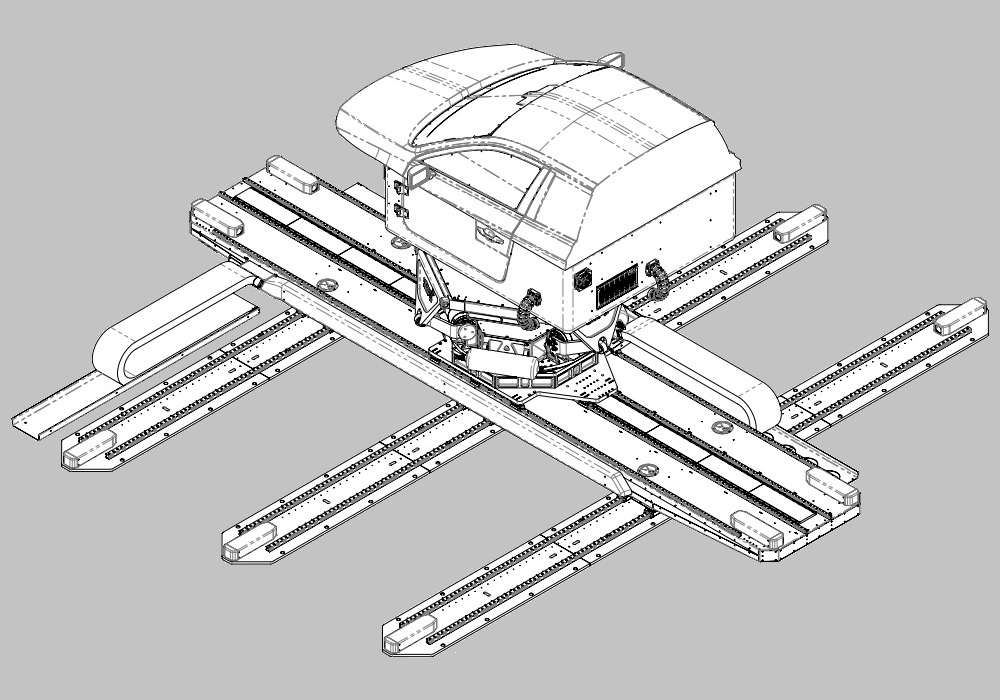

It was becoming evident that our Stratiform Motion System was inherently scalable. The S2 naturally evolved into variants with extended ground plane motion space. The S2e (Stratiform 2 extended) was born.

2020: New directions of growth

The S2e provided customers with new capabilities in experimental space, such as 1:1 (service level) motion in certain lateral, longitudinal and combined events.

Our designers began imagining stratiform evolutions beyond the S2e.

2019-2021: High-dynamics, high-fidelity, high-precision

We began work on what would become the AML SMS2TM, the next evolution of our stratiform topology. Preliminary design studies showed this would exceed our original design goals for performance and scalability. This resulted in a series of new patent applications. New and existing customers took notice.

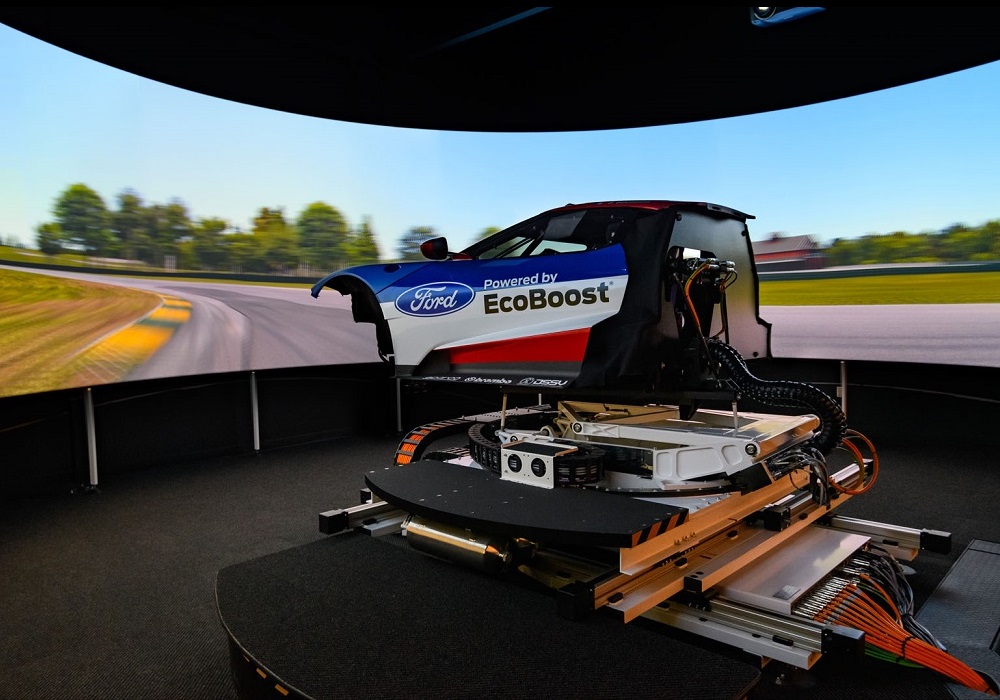

2022: Stratiform 3

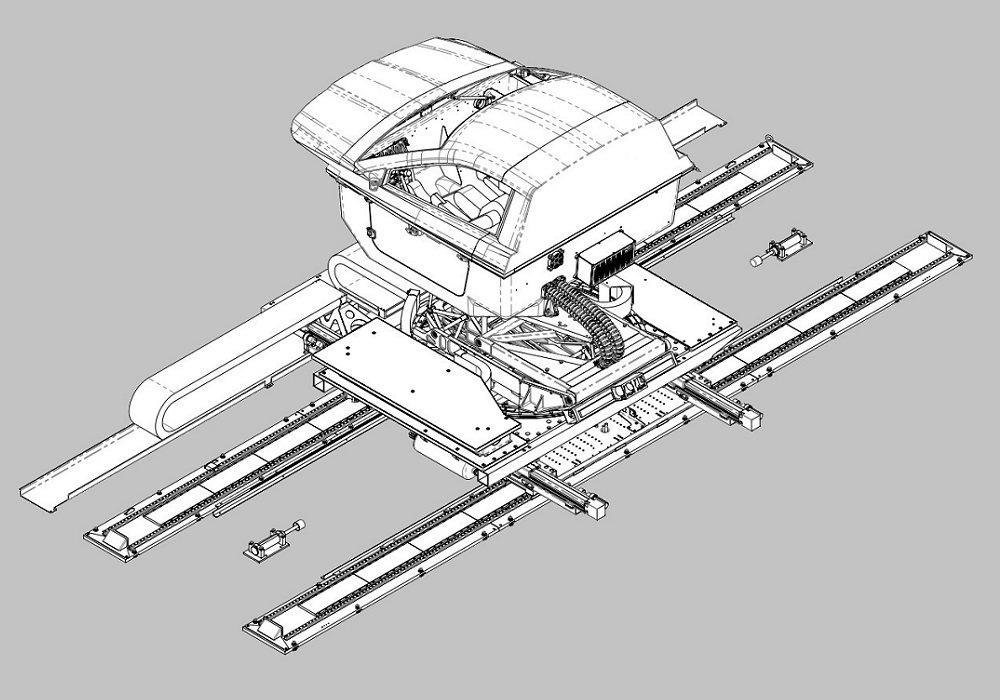

Our latest Delta series DIL simulators now include our proprietary 6-DOF Stratiform 3 (S3) motion system. Larger motion space (4m x 4m baseline ground plane, expandable to even larger); higher payload capacity (500 kg); service level motion and control refinements for all secondary motions.

With multiple size and performance options, the S3 delivers the simulator industry’s most refined physical, dynamic experience.

Ansible Motion is passionate about details. We believe every component, every electrical connector, every user interface is important and deserving of attention.

This is an invitation to visually explore some hardware and software details from current and previous projects.

Ansible Motion Limited

Hethel Engineering Centre

Chapman Way, Norwich

NR14 8FB

UK