Electric vehicles pose many new questions, can driver in the loop simulation answer them? Chris Pickering spoke to simulator manufacturer Ansible Motion

Electric vehicles pose many new questions, can driver in the loop simulation answer them? Chris Pickering spoke to simulator manufacturer Ansible Motion

The stakes are high in such a disruptive environment. Manufacturers that get it right can redefine their brand for the new electric era, whereas others risk going down hugely expensive blind alleys. And with the pressure on to transform quickly, there’s little time to explore different options using conventional techniques.

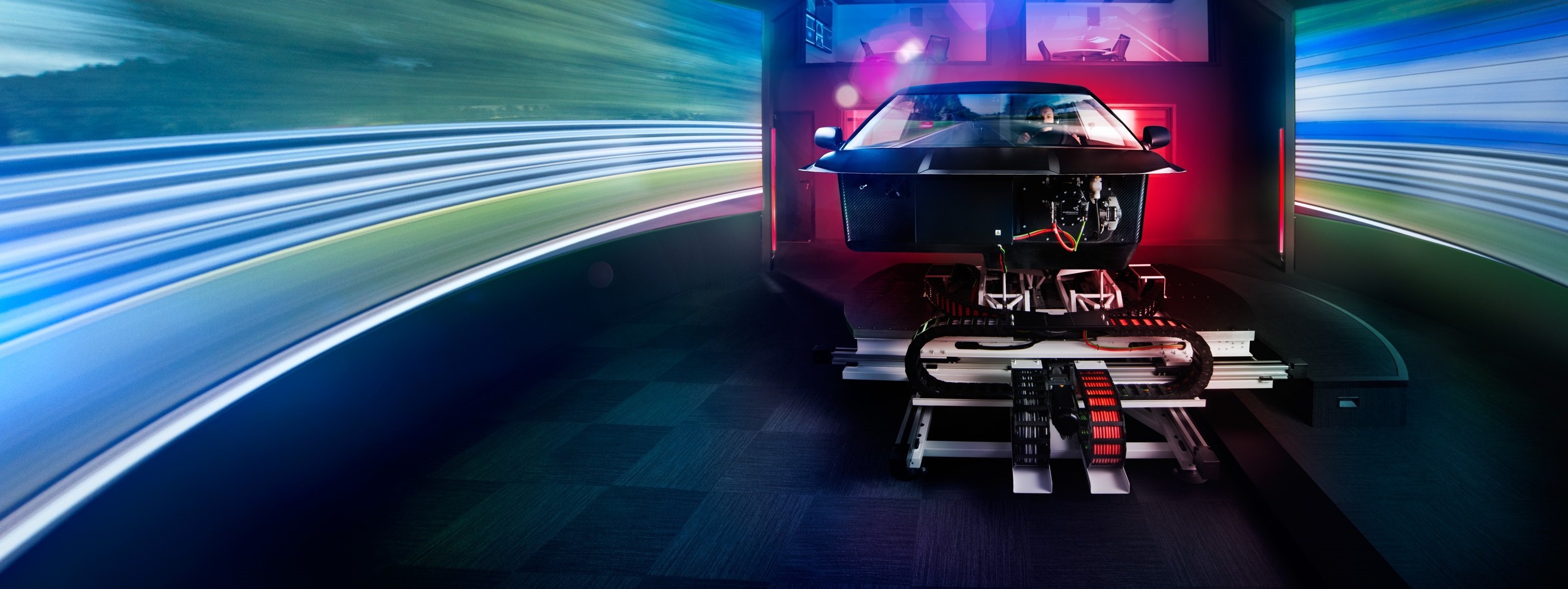

Nestled in a Norfolk industrial estate, just over the hedge from the home of Lotus Cars, sits a company that’s helping manufacturers to confront these challenges. Ansible Motion has a background in motorsport, but these days it supplies driver in the loop (DiL) simulators to some of the world’s biggest carmakers including Ford, General Motors and BMW.

Company founder Kia Cammaerts’ previous work included writing offline simulations for motorsport teams. These mathematically modelled the behaviour of the car to predict its lap time for a given set of vehicle parameters or weather conditions.