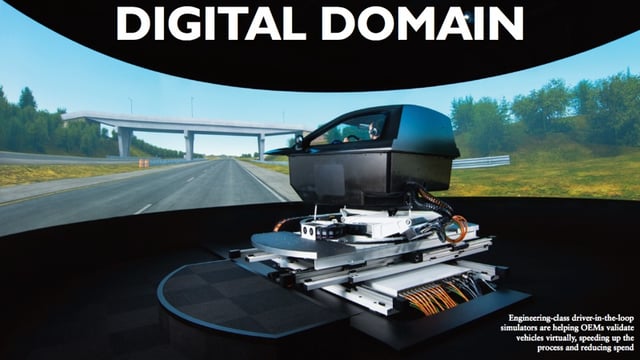

With the costs to develop any new vehicle easily reaching a billion dollars, car makers are keen to uncover savings in R&D budgets. With increasing emissions and safety regulations, the diversity of legislation across the globe, and autonomous cars just around the corner in car development terms, the cost problem isn’t going away anytime soon.

In response to the costs of testing, OEMs and tier ones are increasing their use of simulation tools to undertake an ever increasing amount of the validation. Simulation, at first glance, offers obvious benefits; producing fewer development cars – typically costing $1m for a first prototype – and shaving this from a programme by introducing virtual sign-offs naturally appeals to programme managers.

Now, engineers are increasingly realising that today’s more powerful simulation technologies can, if used correctly, generate richer information that means valuable test track time in real cars isn’t consumed by pedantic validation tasks, but is devoted to making better products and user experiences that can ensure brand acceptance. Phil Morse explains why humans will still have a significant role to play in developing autonomous and ADAS technologies.

Read the article in the latest issue of Vehicle Electronics magazine.