Step into a virtual experience like no other. Ansible Motion driving simulators provide a way to physically experience any ground vehicle – including vehicles that do not yet exist.

From small desktop systems to full-size dynamic simulators, our products deliver class-leading virtual test driving experiences, and are trusted by the world’s top vehicle manufacturers, Tier 1s, motorsport constructors and research institutions.

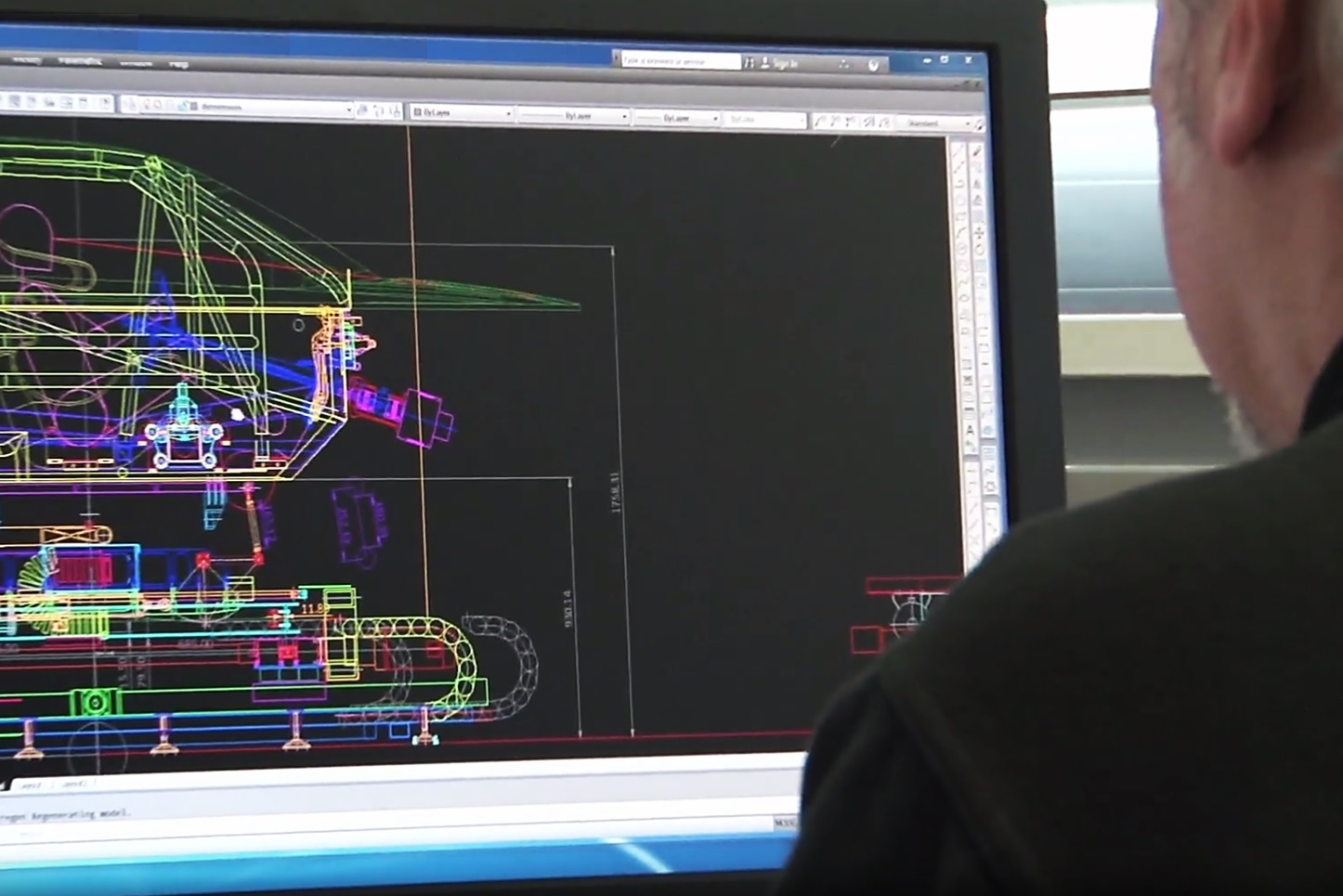

All Ansible Motion simulators are designed, built and commissioned to exacting standards at our factory in Hethel, England.

Dynamic | Full-size | Laboratory

Delta series is our flagship range of dynamic DIL simulators. These provide everything required for high-fidelity, high-dynamic, human-centric vehicle simulations inside a practical laboratory space.

Delta series DIL simulators include Ansible Motion’s patented stratiform motion system which delivers the unparalleled dynamic realism required for many categories of virtual vehicle assessments.

Let Delta series be your first choice when experiments require dynamic immersion and the highest levels of sensory cueing.

Static | Full-size | Laboratory

Sigma series is our range of full-size, stationary DIL simulators. These provide everything required for high-fidelity, human-centric vehicle simulations inside a practical laboratory space where everything except large scale motion can be accommodated.

Sigma series DIL simulators include true-to-life cabin environments that can be equipped with high-level sensory feedback systems, and highly immersive wrap-around, real-time vision systems.

Let Sigma series be your first choice when experiments require realistic immersion and the highest levels of sensory cueing available in a stationary DIL simulator.

Transportable | Compact | Office

Theta series is our range of compact, stationary DIL simulators. These provide a pathway for real people to engage with real-time vehicle simulation environments.

Theta series DIL simulators can be specified as anything from small desktop solutions to simulators with real vehicle seats and dashboards, so they are ideal for smaller spaces such as office environments,

Let Theta series be your first choice when experiments require a compact driving simulator with the computational power to connect to engineering class physics, HIL, SIL and scenario tools.

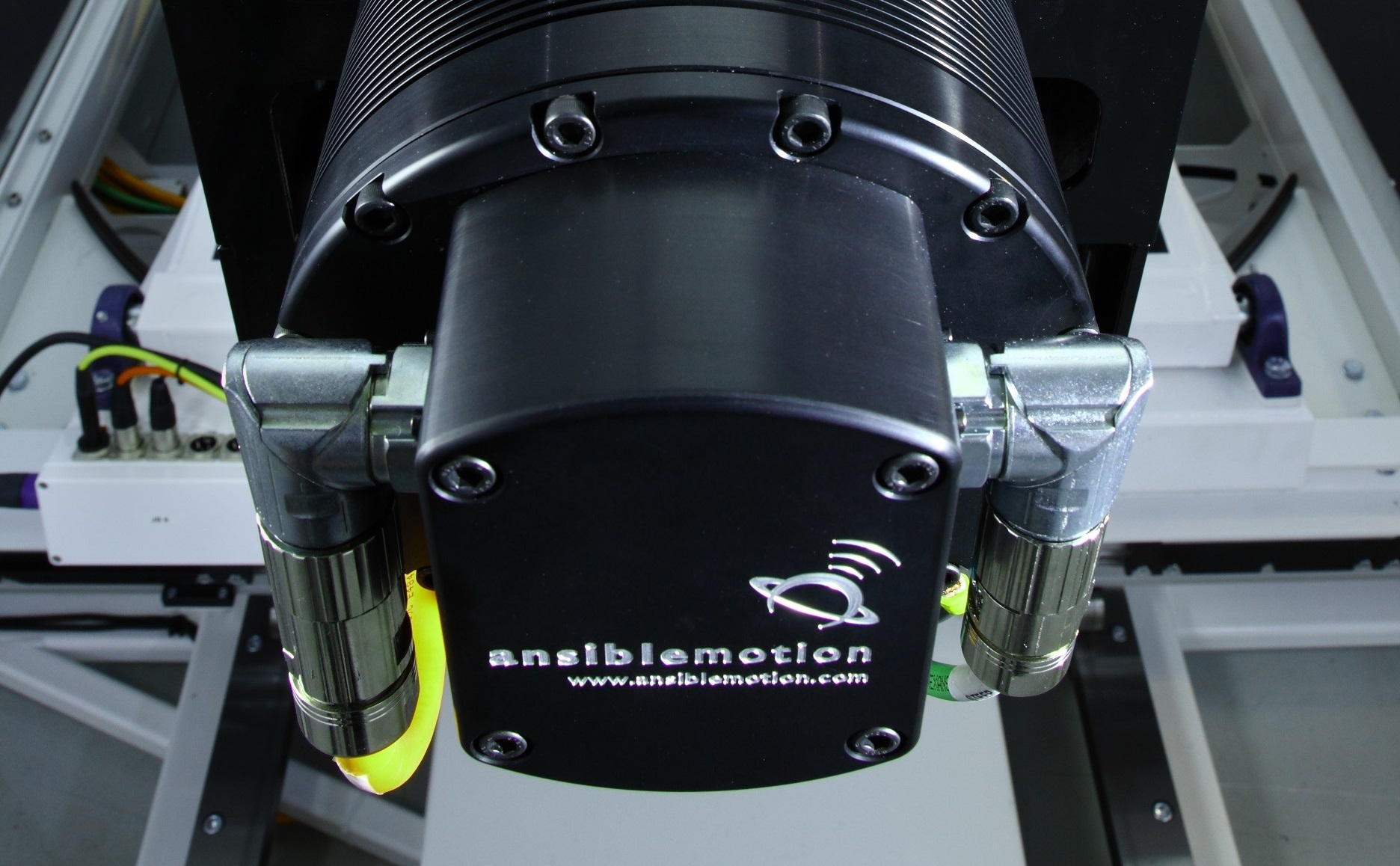

Subsystems | Special designs | Services

Ansible Motion provides a full range of products and services for anyone wishing to upgrade an existing DIL simulator, or build their own DIL simulator using trusted components.

We have DIL-specific domain experience in hardware, software, integration, mechanical and electrical design, field support, facilities planning, logistics and more.

Let Ansible Motion be your primary resource when you need any type of technical service or operational assistance with your driving simulator projects.

Driver-in-the-Loop (DIL) has become an industry standard name for automotive Human-and-Hardware-in-the-Loop (H2IL) simulation. Driver-in-the-Loop is a fitting name.

Sometimes the Driver is the person immersed inside a simulator cabin who is participating as a vehicle pilot, as a passive occupant or in a mixed-mode role. Sometimes the Driver is a ride and handling evaluator, or a program manager or an entire team of stakeholders. In all cases, DIL simulation is “driven” by human participation in virtual worlds.

How can Ansible Motion help you drive your projects?

Ansible Motion focuses exclusively on developing, delivering and supporting Driver-in-the-Loop (DIL) products and solutions. There are no distractions from our primary mission, making us unique among DIL simulator providers.

Our customers benefit directly from our laser focus. Our passion for DIL simulation translates into a laser focus on doing it right. Our engineering, design, applications and field support teams are always at the ready to help our customers succeed.

Ansible Motion’s multi-application DIL simulators are solid investments that pay real returns through reduced development costs and environmental impact. Return on Investment (ROI) justifications go well beyond reducing physical prototypes.

Early and often human contact with proposed vehicles and systems is key to catching problems early – when they can be safely and efficiently addressed with minimal cost implications. Use of DIL simulation leads directly to product quality improvements that improve brand perception and boost product sales, and has the potential to mitigate warranty costs. DIL simulation is also an inherently green technology that reduces the carbon footprint of traditional vehicle development programmes, due to significantly reduced resource consumption.

Ansible Motion Limited

Hethel Engineering Centre

Chapman Way, Norwich

NR14 8FB

UK